Autonomous Maintenance-Planned Maintenance

Equipment Management - Layout Consulting

.png)

.png)

OpEx advisors are waiting for you

You are in the right place for OpEx (Operational Excellence) consultants! As KPI ACADEMY, we offer customized consulting services for businesses to optimize their operational processes and increase their level of excellence. Our expert OpEx consultants offer strategic solutions to increase the efficiency of businesses, reduce waste, reduce costs and gain competitive advantage. Working with our OpEx consultants, you can analyze your business processes, identify opportunities for improvement and target operational excellence.

We are waiting for you!

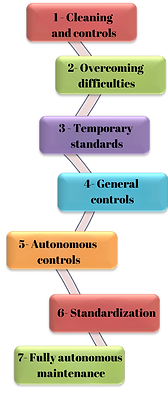

Autonomous maintenance

Autonomous Maintenance is a maintenance approach in which operators take responsibility to improve the operational performance of enterprises' equipment and machinery and to prevent failures in advance. Operators undertake routine tasks such as daily cleaning, maintenance and minor adjustments, keeping equipment operating in optimum condition. Autonomous Maintenance makes machines run more reliably, reduces downtime and lowers maintenance costs.

Planned Maintenance

We redesign all the processes made in your factory. While investing in your operators and machines with Autonomous Maintenance, we aim to eliminate unnecessary workload with planned maintenance and have your company have a team that can solve its problems with its own maintenance team and resources.

With Layout Consulting, we offer you the design, projecting and management support of the production lines that you will establish in your company.

Equipment Management and Layout Consulting

Increase Business Efficiency

Equipment management and layout consultancy aims to ensure that businesses manage their equipment effectively and provide an optimal layout in the workplace. Proper equipment management and layout planning play a critical role in increasing the efficiency of businesses, reducing waste, reducing labor costs and optimizing business processes.

Services

-

Equipment Inventory and Situation Analysis

Equipment inventory and condition analysis is the process of creating a complete inventory of equipment owned by a business and evaluating its current condition. This analysis is done to determine the number, type, age, availability and general condition of the equipment of the enterprise. Equipment inventory and condition analysis play a guiding role in determining the equipment management strategies of the enterprise and in the maintenance planning processes.

-

Equipment Layout and Flow Analysis

Equipment layout and flow analysis aims to place the enterprise's equipment in the most suitable locations in the workplace and optimize the flow of business processes. This analysis evaluates the layout of the business's production line or workplace and is used to examine equipment layout, material flow, layout of workstations, and operational efficiency. Equipment layout and flow analysis help the business make strategic decisions to improve efficiency, reduce waste and streamline business processes.

-

Equipment Usage Optimization

Equipment usage optimization aims to use the existing equipment of the enterprise in the most effective way. In this process, equipment utilization rates, uptimes and productivity levels are analyzed. Equipment utilization optimization increases the availability of equipment by minimizing downtime, reducing process downtime and increasing the productivity and profitability of the business.

-

Equipment Maintenance Planning and Tracking

Equipment maintenance planning and tracking is the process of planning and monitoring the regular maintenance and repairs of the company's equipment. In this process, maintenance programs are created, preventive maintenance activities are planned, and a regular maintenance schedule is followed. Equipment maintenance planning and tracking helps prevent equipment failures, keep maintenance costs under control, and extend equipment life.

-

Equipment Performance Measurement and Improvement

Equipment performance measurement and improvement is the process used to monitor, analyze and improve the performance of an enterprise's equipment. In this process, performance indicators such as equipment efficiency rates, uptimes, downtimes and failure frequency are evaluated. Equipment performance measurement and improvement optimizes the performance of the enterprise's equipment, increasing efficiency, reducing waste in processes and increasing the competitiveness of the enterprise.

What We Do

As KPI ACADEMY, we offer businesses customized consultancy and training services on equipment management, autonomous maintenance and scheduled maintenance. Our expert consultants provide strategic solutions to enable businesses to best manage their equipment, improve operators' autonomous maintenance skills and optimize their maintenance processes. We analyze businesses' equipment inventory, optimize layout planning, improve equipment utilization and performance, create maintenance schedules, and help businesses increase their operational efficiency. Our goal is to help businesses make their equipment run more efficiently, reduce the risk of failure, and achieve operational excellence.

_edited.png)